PHE - Products

UMM AL QUWAIN RUBBER INDUSTRIES LTD

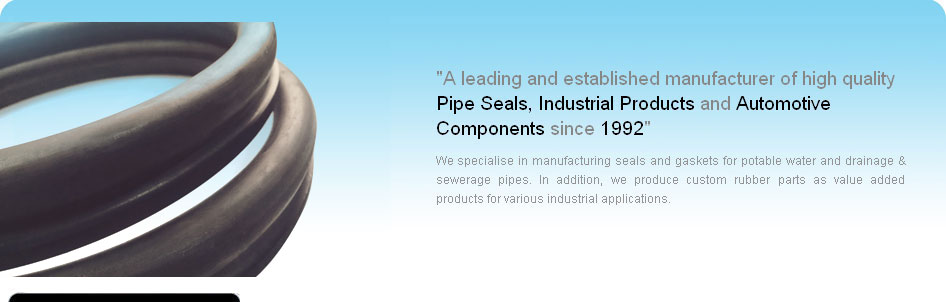

Located in UAE, URIL is a leading and well established manufacturer of seals & gaskets in Gulf region since 1992. In the year 2000 we started manufacturing PHE gaskets & and now we have 14 yrs of experience in manufacturing PHE gaskets for reputed OEM’s.

Our success is built around one goal: “TO EXCEED OUR CUSTOMER’S EXPECTATIONS”. URIL takes you from concept through production in the most efficient and cost-effective manner.

For more than two decades, customers have been drawn to our quality, efficiency & competitive prices… and have stayed for the service. We are experienced in handling a wide variety of elastomers for a diverse range of industries.

Working hard in hand with our customers we develop products for specific requirements and solutions that really work.

With the available resources we have the capacity to produce more than 500,000 PHE gakets per year.

Our quality systems are recognize wit ISO 9001 approval and we have been a BSI registered firm since 1997

GASKET CHARACTERISTICS

Compression set: The rubber compound can change shape after being squeezed it will restore to its original vulcanized shape

Strength : It is strong enough to withstand the forces normally incurred by squeezing into position and being acted upon by pressurized liquid.

Hardness Range : The rubber is strong enough for the application but still soft enough to conform closely to the metal surface and provides a seal without undue stress being applied.

Resistance : The high molecular weight, cross linked polymer matrix is resistant to penetration by any fluid of a dissimilar chemical nature to itself.

Temperature : All Polymers will only behave as a rubber over a relatively short range of temperature. Thus careful selection of the compound according to the required temperature range is necessary.

Life : Synthetic polymers have a built in superiority in terms of useful lifetime, and modern additives can further enhance this property. It is in this area that the correct compound selection is of vital importance.

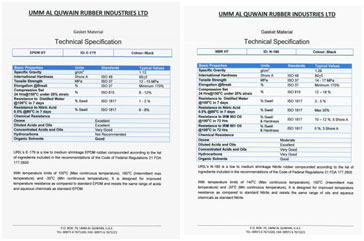

COMPOUNDING

Polymers alone have few uses in their natural state. To achieve the desired range of properties, the raw rubber must be combined with a range of additives. The additives in a rubber compound are as follows:

- Curatives

- Accelerators

- Reinforcing Fillers

- Fillers

- Plasticizers

- Anti – Oxidants / Anti - Ozonants

Although, we have compound suitable for customer’s need, our experience in polymer engineering enables the development of new compound to meet special requirements.

For PHE gaskets following compounds are normally used

- NBR – HT

- EPDM – HT

- NBR B (for Low Temperature Application)

- FKM

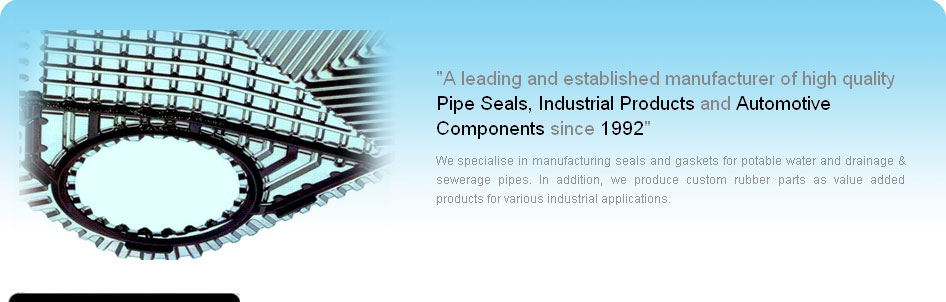

MOULD MAKING

We are capable of producing gasket moulds with the available database of plates dimensions, or by the plates and gasket sample supplied by customers as per requirement.

URIL have a highly trained skilled workforce & make the best use of the facilities available ensuring quality for our customers.

With the available mould making facilities we are able to manufacture moulds reducing lead times & ensuring consistently high quality product is available to our clients as per schedule.

This combination of speed and quality promotes the enhanced confidence that clients have in URIL’s service.

EXTRUSION

Cold Feed & Barwell extruders

MOULDING PROCESS

High tonnage shuttle compression moulding presses Post curing ovens with traceability system.

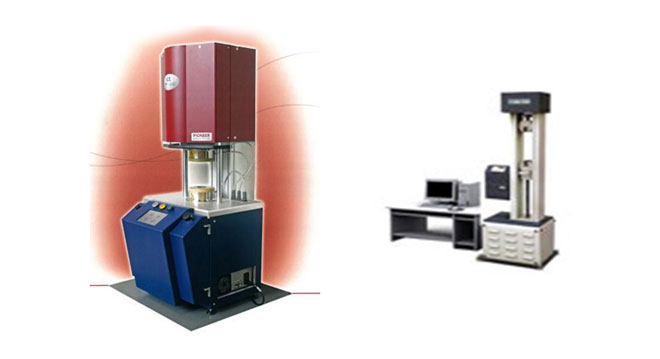

QUALITY CONTROL

Our Laboratory is equipped with following:

- Rheometer,

- Tenso Meter

- Lab Ovens

- Aging Test Equipments

- Compression Set Testing Equipment,

- Shore “A” Hardness Tester.

- Profile projector

- Liquid Immersion testing equipment

| APV | ALFA LAVAL | GEA | SONDEX | API HEAT TRANSFER |

| FP10 | M10B | NT150L | S100 T CLIP | SIGMA 17 STICK |

| FP16 | M10M | NT150S | S14 | SIGMA 27 STICK |

| FP31 | M15B | VT10 | S22 | SIGMA 37 STICK |

| FP40 | M15M | VT10 DITCH | S43 | SIGMA 7 CLIP |

| H RING FD | M6 | VT20 | S47 | SIGMA 9 CLIP |

| H17 | M6M | VT4 | S62 | SIGMA 9 STICK |

| K RING BD | T20B | VT40 | S86 | SIGMA X 13 CLIP |

| K RING FD | T20BW | VT80 DITCH | SIGMA X 29 CLIP | |

| FK34 STICKP16 | T2B | SIGMA X 49 | ||

| N RING FD | TL10B | |||

| N25 STICK | TS20M | |||

| N35 | TS6M | |||

| N50 | M10B | |||

| QD030 | M10M | |||

| QE030 | M15B | |||

| QE055 | M15M |